The Macaos Assembly Data Manager supports viewing and editing component assembly data for a PCB.

Please note: The Assembly Data Manager is only available in Macaos Enterprise EMS. This feature is not included with the Basic or PreCAM versions.

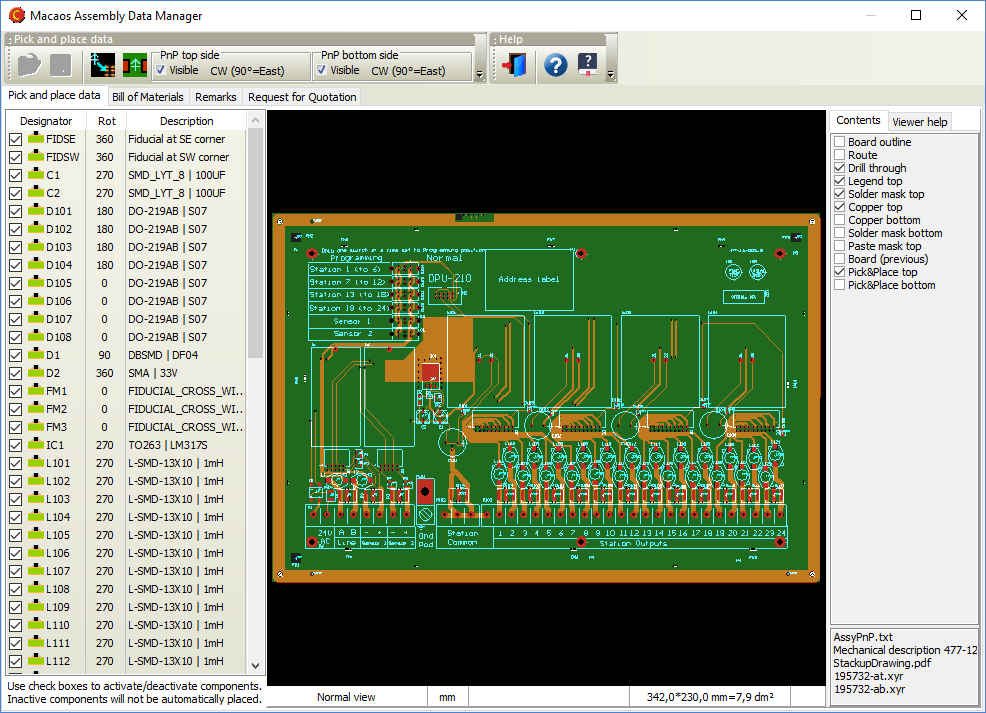

Pick and place data

Pick and place (PnP) data is used by automatic component placement machines to place the correct component, with the correct orientation at the correct position on a PCB prior to soldering. At the minimum, PnP data consists of a designator, x and y coordinates, a rotation and a description.

With the Macaos pick and place manager, you can:

- View and inspect PnP data imported together with Gerber files

- Import PnP data to the product

- Align PnP data with the PCB product data

- Select which components should be machine-placed

- Edit individual components (layer, rotation, designator, description)

- Add individual components

There is unfortunately no formal or de-facto standard format for PnP data. Macaos is able to automatically detect and read about 30 different formats, generated by the most common CAD system.

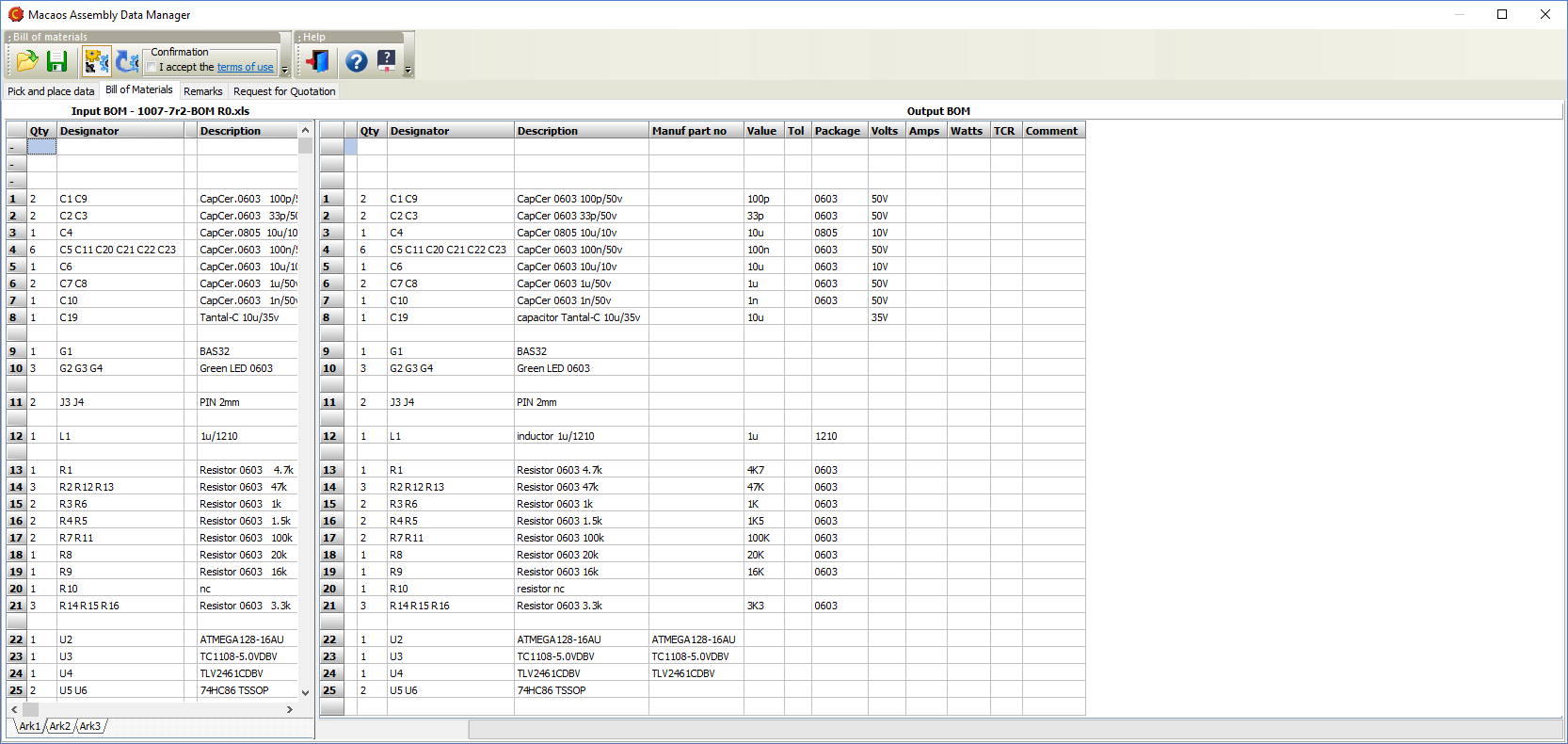

Bill of Materials data

A Bill of Materials (BOM) is a list of the components on a PCB. The BOM is used to select and purchase the correct components as well as to specify where each component should be placed on the printed circuit board.

Frequently, a BOM generated by a CAD system or inventory system may not contain enough information for a purchaser to accurately select the correct components.

The Macaos BOM screener can help to clarify things. It attempts to parse the information in the BOM, extracting relevant parameters (such as component type, value, voltage, tolerance, etc) into a structured spreadsheet. You may then easily add additional specifications for components which are underspecified.

Remarks

Graphical remarks may be added by drawing a circle around an area on the PCB, and then entering a text, which will be shown to the right of the circle. This can be useful for special instructions for specific components.